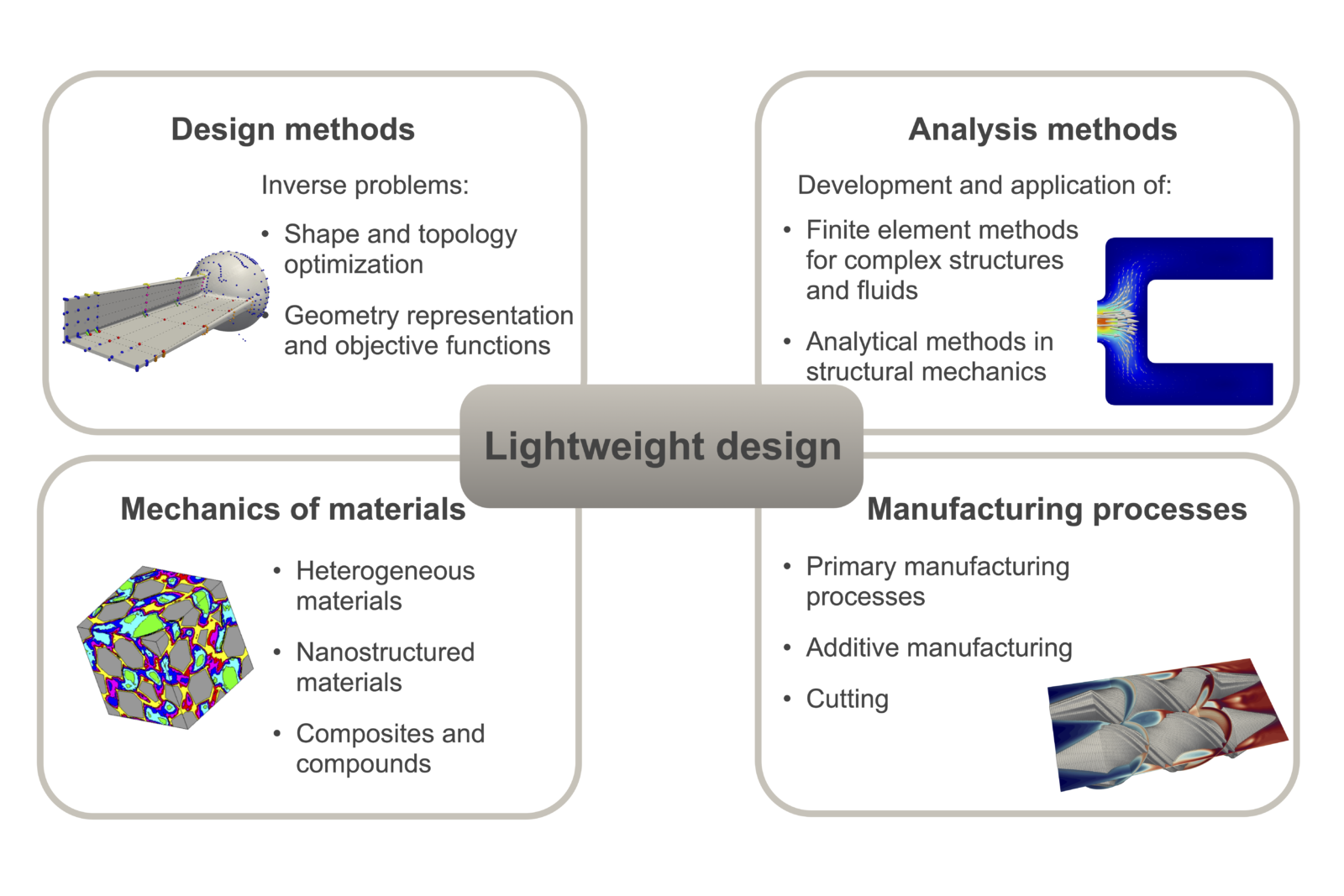

Lightweight design refers to the development and design of structural components that fulfil their desired functionality under the given boundary conditions with minimal material usage/weight. Not only does the reduced amount of material lead to cost reduction during both manufacturing and usage, but there is also an immediate effect of reduced exploitation of resources.

Modern lightweight design is required to address the fields of development and design, analysis, material design, and production engineering. To unite these fields under one roof is the specialty of the lightweight design group at ILSB. The group’s research goal is the development of application-specific numerical methods and their utilization in numerical design. These goals are achieved as part of fundamental research projects funded by national or international research foundations, but at the same time, our research results stem from collaborations with industrial partners on specific problems.

The fields of interest not only include nonlinear modelling and simulation of the thermo–mechanical properties of a variety of structures and composites, reaching from nano-structures to whole components, but also extend to the numerical design of the corresponding manufacturing processes. The analysis is based on both analytical and numerical approaches and includes the development and implementation of algorithms.

With respect to design, classic optimization algorithms are combined with model order reduction and machine learning. One core competence of the research group is geometry representation using splines, which is employed in shape optimization, but also in numerical simulation by means of isogeometric analysis.