Fuels as chemically bound energy carriers will continue to play a dominant role in mobility due to their advantages in terms of energy density as well as transport and storage. This applies in particular to aviation and marine applications, but also to vehicle powertrains. It is essential that the switch from fossil fuels to sustainable generation will be successful. Below are some examples of current activities at the IFA in this area:

Regenerative gasoline fuels – e-Fuels

Regeneratively produced drop-in fuels that meet the current EN228 fuel standard can be used in the existing vehicle fleet and bring an immediate reduction in CO2 emissions.

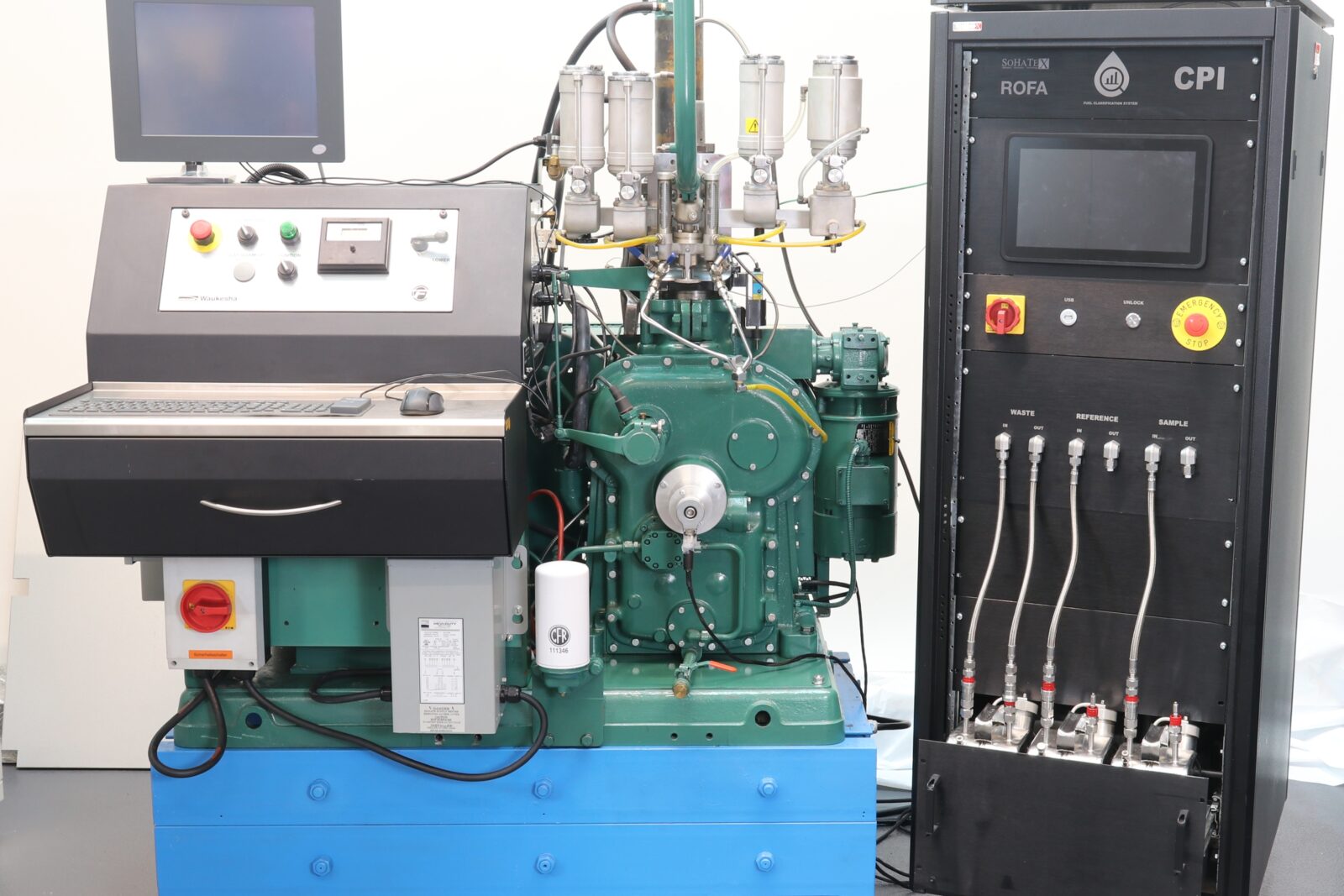

Particularly on modern, highly supercharged downsized engines, it is essential that, in addition to the minimum requirement specified in the standard about knock resistance (octane numbers MOZ, ROZ), undesirable preignition (LSPI) does not occur even in the low-speed range. A new test method, based on a modified CFR test engine with direct injection and turbocharging, was developed with project partners at the institute. The latest CPI (Compression Pre Ignition) fuel index is to be included in the fuel standard as a new quality criterion in the future.

Bio natural gas

The institute is working on alternative, climate-neutral fuels such as CNG (compressed natural gas) produced from biomass. The properties of the main component, methane, enable process control with the high power density and fuel efficiency.

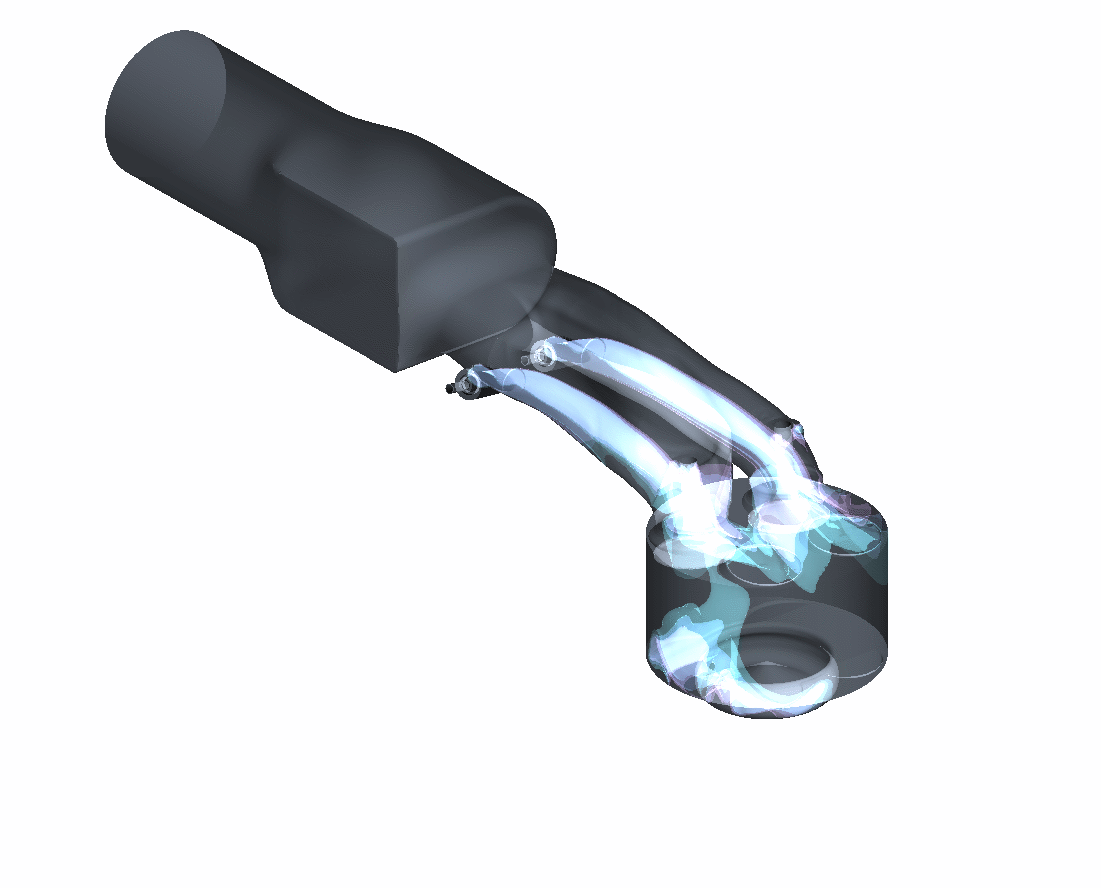

An innovative concept is a direct injection into the combustion chamber, which avoids the displacement effect in the intake manifold and the scavenging of the fuel gas. Research has been carried out at the IFA to exploit these properties using optimized timing and turbocharging. For example, low-end torque has been significantly improved, which, together with “downspeeding” concepts, is very beneficial for fuel consumption.

Another benefit of direct injection is catalyst heating through additional injection into the expansion stroke. The late combustion then leads to accelerated catalyst heating, which significantly reduces emissions.

Hydrogen

Regeneratively produced hydrogen is a promising energy carrier for achieving the upcoming climate targets and reducing anthropogenic CO2 emissions. There are several reasons for using hydrogen in combustion engines. On the one hand, it is possible to use a well-established and well-known technology. On the other hand, the cooling system and the hydrogen quality requirements are significantly lower than for a fuel cell, for example.

At the institute, a hydrogen combustion engine is currently being developed with an industrial partner for use in small aircraft. The hydrogen-air mixture generated by external mixture formation is ignited in the combustion chamber with the aid of a small quantity of kerosene. This so-called dual-fuel process makes it possible to switch to conventional pure kerosene operation at any time in the event of supply difficulties. With only a few engine adaptations, a significant reduction in pollutant emissions, especially CO2, is possible.

Wood gas

Multi-fuel engines can be operated with various gaseous fuels. They are primarily used in combined heat and power plants (CHP) for a self-sufficient and decentralized supply of electricity and heat. Biologically produced gases such as biogas, wood gas, sewage gas, and landfill gas are used as fuel for the gas engine. These gases are CO2-neutral and make a valuable contribution to a rapid transformation of the global energy sector.

Since the gas generation process results in lower heating values and a fluctuating composition of the gas mixture, each engine must be adapted to the specific fuel properties to ensure efficient engine operation, durability, and low pollutant emissions.

At the Institute, a combined simulative and experimental approach is taken on the 1-cylinder research engine to optimize the combustion process. For the provision of the gas mixtures, a gas mixer has been developed that enables online provision of the defined gas composition (i.e., biogas, wood gas, sewage gas, or landfill gas). This allows engine operation to be simulated and precisely investigated on the engine test bench.

The flexible setup enables research work on various optimization measures and engine technologies, such as turbocharging, high-energy ignition systems, water injection, exhaust gas recirculation, and optimization of combustion chamber geometry.

Contacts:

Univ.Prof. Dr. Bernhard Geringer

Phone: +43 1 58801 31500

bernhard.geringer@ifa.tuwien.ac.at

Assoc.Prof. Dr. Peter Hofmann

Phone: +43 1 58801 31576

peter.hofmann@ifa.tuwien.ac.at