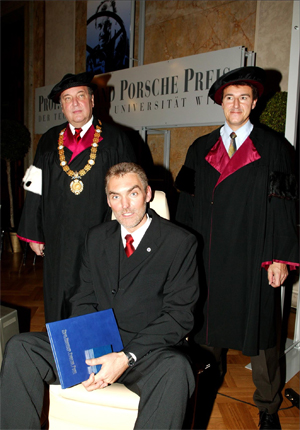

The most highly endowed automotive engineering award, the “Professor Ferdinand Porsche Award 2003” of the TU Wien, was presented to Mr. Dip.-Ing. Uwe Borchers of Johnson Controls at an academic ceremony on October 10, 2003, for developing the 18-way seat, which was first used in the VW Phaeton. The previous Porsche award winners were primarily characterized by safety and energy-saving considerations. This year, for the first time, the selection jury chose an innovative solution in health and comfort – the current zenith for seat design in a passenger car.

Dipl.-Ing. Uwe Borchers was awarded the Prof. Ferdinand Porsche Award for his work in developing and manufacturing the so-called 18-way seat from Johnson Controls.

This high-end seat, originally developed for the VW Phaeton, has 18 independent and electrical adjustment options, as the picture shows.

This makes it possible to realize an almost unlimited range of variations for optimum and individual adjustment.

It is known that almost 80% of the population suffers from back pain; due to the many sedentary activities of modern man, this problem occurs increasingly today. Especially the vehicle, and here, in particular, the upper and luxury class, make very special demands on the seating quality and the “feel-good atmosphere” (due to the usually very long stays in these vehicles; yes, often up to 2 hours a day). Comfortable and convenient seating systems that enable fatigue-free driving help to make the time spent in the automobile as pleasant as possible.

The seat design of the 18-way seat offers, due to the multiple adjustment possibilities, the unique possibility – depending on the driver’s size and constitution, from the petite lady to the tall and muscular man – to find his ideal position. This targeted ergonomic optimization enables fatigue-free driving and, at the same time, creates greater safety.

However, the best possible seat climate control is also required for a pleasant and relaxed ride.

As shown in the new 18-way seat, good seat cushions are achieved by a newly developed inner seat structure with uniform flow through the seat surface – supplied by dedicated flow channels directly under the leather cover – and distribution in the seating area.

This picture shows the results of the calculated 3-D flow areas in the support area. With the most modern means – not even available a few years ago – a very high degree of maturity could be achieved here.

However, the air and contact pressure distribution in the seating area are decisive for the passenger’s well-being. Objective comfort measurements and visualization of the results enabled the seat design to be optimized early in development. This approach to development also offers excellent reference possibilities for comparative measurements during subsequent series monitoring based on the objectification of the data.

Finally, from the optimization details of this new high-end seat, I would like to show a photograph of the representation of the climatic conditions. To evaluate the seat heating, recordings were made with the thermal camera, and from this, improvement and optimization were achieved to an extent hardly known before.

This seat design and optimization, carried out with great effort and creativity has already received great approval and positive criticism in the trade press. Above all, reference should be made here to the award already made with the so-called “AGR seal of approval – for tested and recommended seat design.”

The award publication noted that “the problem of a back-friendly design, apparently presented as insoluble for many car seats, has been successfully solved for the development of the 18-way seat, making optimal travel feasible”.