We are excited to announce a new publication with contributions from our CD lab members, featured in Mechanics of Materials, titled “The viscoelastic behavior of lignin: Quantification through nanoindentation relaxation testing on hot-pressed technical lignin samples from various origins.” This paper marks a significant advancement in our understanding of lignin, a natural polymer with vast potential in renewable resources and sustainable materials.

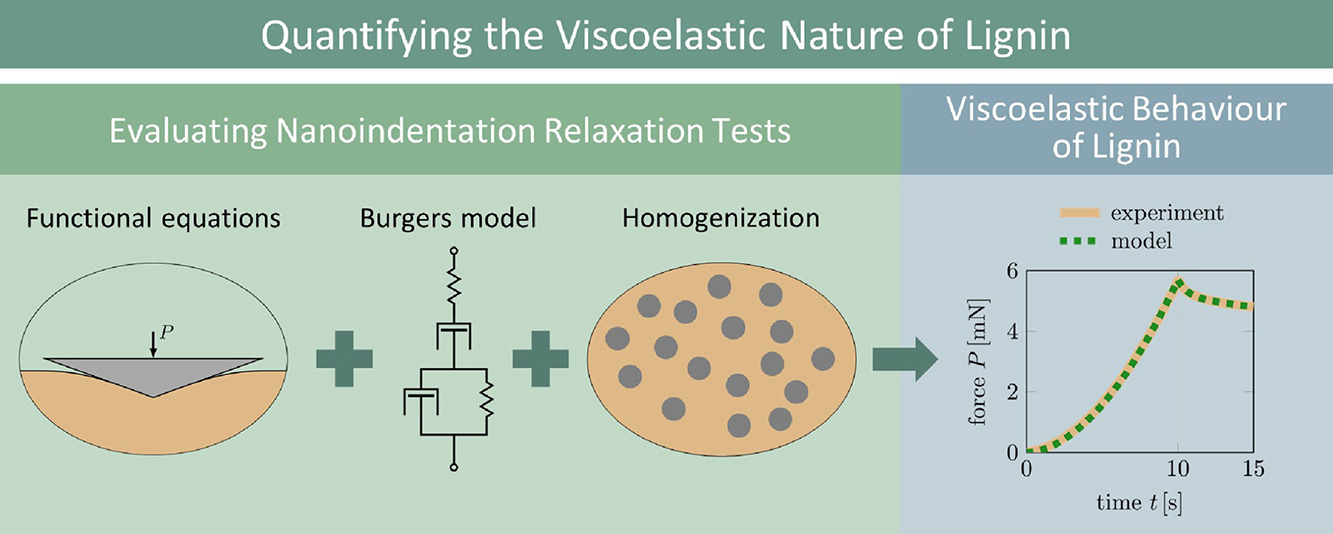

Nanoindentation relaxation tests assessed via micromechanics

The study focuses on the viscoelastic behavior of lignin, a crucial aspect of its potential applications in various industries. The research team conducted nanoindentation relaxation tests on several hot-pressed technical lignin samples sourced from different origins. The findings reveal a consistency in the viscoelastic properties of these samples, regardless of their origin or extraction process.

The observed viscoelastic behavior of solid (i.e., pore-free) lignin could be accurately modeled as an isochoric material with a constant bulk modulus and a time-dependent shear behavior resembled by a four-parameter Burgers model.

Advancing the applicability of lignin-based biocomposite materials

This discovery is pivotal as it suggests a broader applicability and reliability of lignin in developing sustainable materials. Lignin, often a byproduct of the paper and pulp industry, holds promise in advancing wood-based biocomposite materials and their production methods.

This work contributes to a deeper understanding of lignin’s mechanical properties, which are essential for innovating and optimizing its use in sustainable applications. This research highlights the potential of lignin as a versatile biomaterial and underscores the importance of sustainable practices in material science.

For more details on our findings and their implications, we invite you to read the full paper available.

WoodComp3D

WoodComp3D