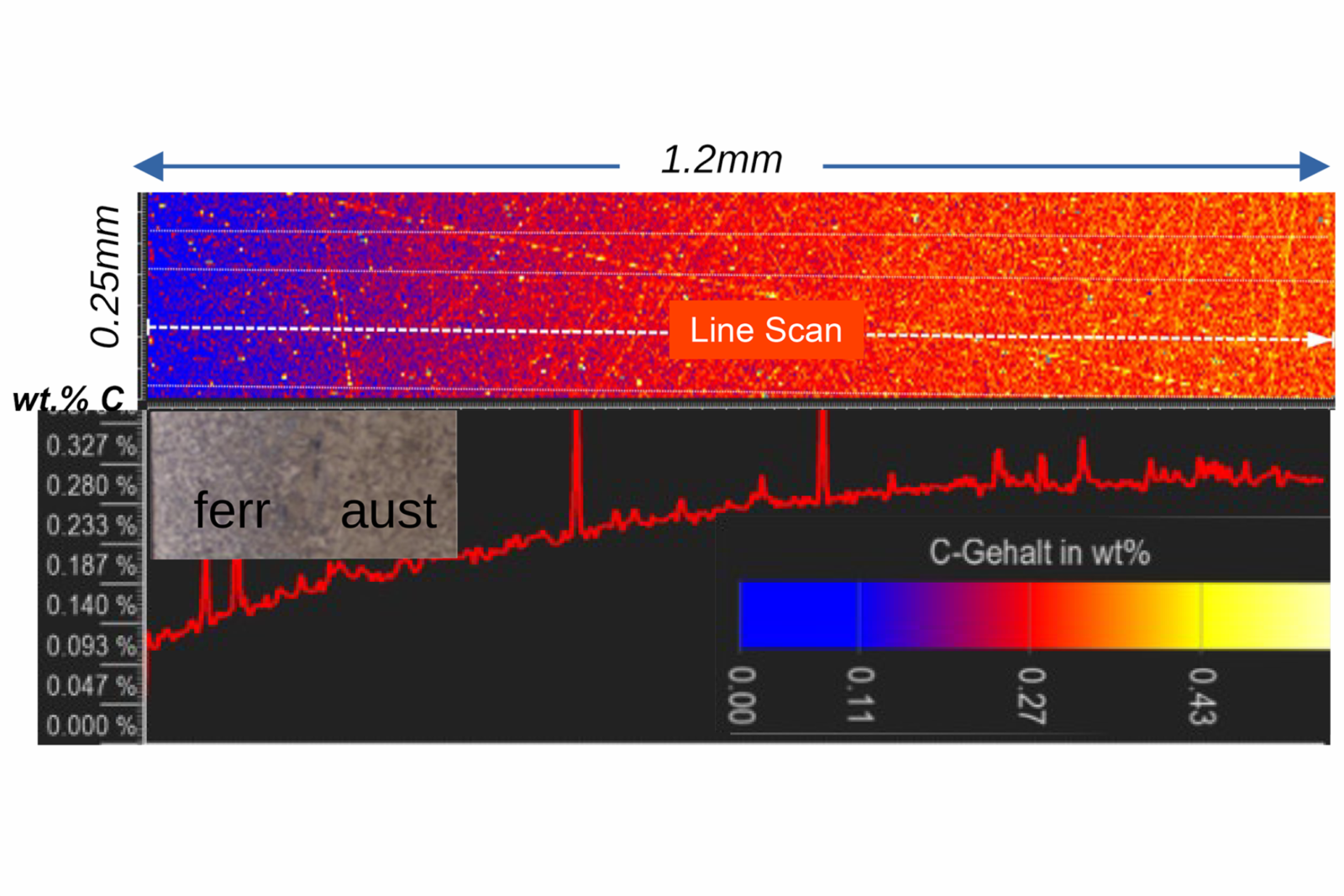

The EPMA (electron probe micro-analysis) mapping in the upper half shows the carbon fraction in the region from the surface up to 1.2 mm into the material. A line scan in the lower half, orthogonal from the surface into the fabric, pictures the carbon concentration gradient. In the carbon-depleted surface near regions, ferrite is more stable than austenite.

It is generally known that Boron nitride, BN, deteriorates materials properties in Boron-alloyed steel. It is also expected to date that TiN can bind nitrogen sufficiently, thus preventing BN formation. However, our TEM results show that BN is not always prevented with presence of TiN, since nano-ensembles of TiN-AlN-BN do not only bind nitrogen, but also Boron, which is then no longer available as dissolves pecies within the steel matrix (a requirement for the „Boron effect“ on the hardenability of Boron-microalloyed steel).